Follow Us x

"A person who never made a mistake never tried anything new"

- Albert Einstein

We partnered up with Don Mashburn, Inc. to provide the industry with a selection of BHA filtering solutions. The innovative products are designed for today's drilling challenges and continue to evolve as wells become more complex. We are confident that our 30 years of drilling industry experience can help companies achieve continuous performance improvement. We take the TFF out of daily operation reports.

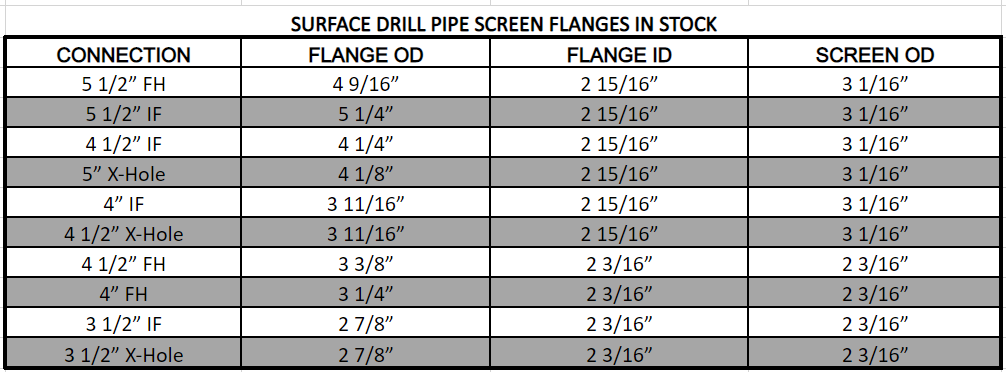

Drill Pipe Screen

Protect the BHA from debris with the first bar-type design and an industry-leading drill pipe screen.The drill pipe filter screen provides protection from surface debris often found in the circulating system while maintaining the integrity of the mud properties.

The top flow cap, wireline fish neck, and retainer rings are precision machined and made of 316 stainless steel. The design features provide a linear flow at high GPM rates withstanding erosion and eliminating the risk of a washout.

The screen is wireline retrievable. We have a large inventory to support different drill pipe sizes allowing for quick delivery.

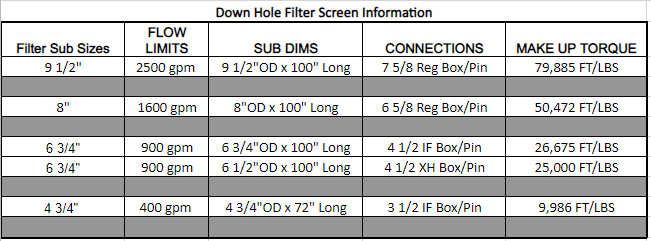

Downhole Filter Screen

A top-performing downhole filter screen used by many Directional, MWD/LWD, and Reamer service companies around the world, the patented DMI screen reduces the risk of a trip for failure from debris and other foreign content in the mud. The unique high flow design filters debris effectively and the bypass feature allows for continuous operation in the event the screen becomes full.

The DMI downhole filter screen design has improved over the last 29 years by using historical bit run data, feedback from the customer, and the engineering software SolidWorks Simulator. The filter is NS-1 certified with nuke source retrievable access and is currently operating in 19 countries. The screen design has often been imitated but never duplicated.

Surface Inline Filter Screen

Surface Inline Filter Screen

A Game Changer, the Surface Inline Filter Screen is a new product design built for today's drilling operations. The engineers at DMI identified the technology gap as the industry moves toward strict HSE drop guidelines and rig automation.

The unit incorporates the DMI drill pipe screen benefits in an innovative inline flow design allowing easy access for servicing and eliminating the drop hazard.

The unit features a small footprint, 5" flow line, 1002 hammer union connections, safety ball valves for isolation, and spill containment. The unit is tested to 7500 psi for pressure integrity and recorded.